Reveal the Possible: Materials Test Lab Insights for Success

Wiki Article

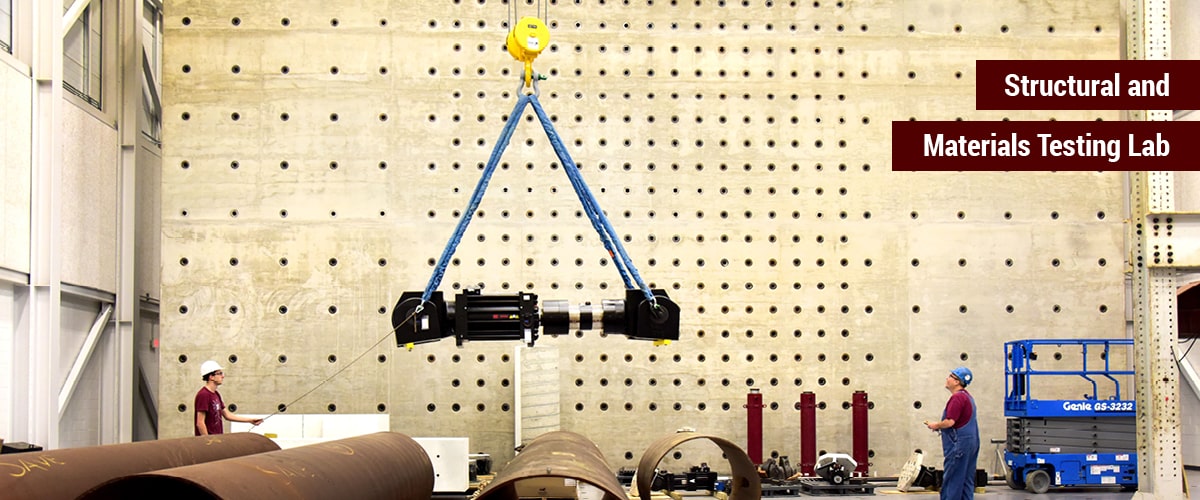

Materials Testing Laboratory: Evaluating Efficiency and Safety

In today's busy globe, ensuring the efficiency and safety of products is of utmost importance. This is where products examining laboratories play an important function. These specialized labs are geared up with cutting edge testing methods to examine the performance and safety of various products. From steels and plastics to concrete and textiles, materials evaluating labs provide reliable and exact outcomes to sectors throughout markets. By subjecting materials to rigorous examinations, these laboratories supply useful insights right into their mechanical residential or commercial properties, durability, and resistance to ecological aspects. This info helps designers, makers, and researchers make educated decisions concerning material option and usage, eventually adding to the general quality and safety and security of products and frameworks. In this short article, we will certainly explore the significance of products screening, the techniques included, and the advantages of exact test outcomes.Significance of Products Screening

The significance of products screening in guaranteeing performance and safety can not be overstated. Products screening plays an important duty in numerous sectors, from aerospace and automotive to building and construction and manufacturing. By subjecting materials to strenuous testing treatments, scientists and designers can review their buildings, efficiency, and resilience under different conditions. This enables them to identify whether the materials meet the required specifications and criteria, ensuring the safety and dependability of the end product.Products testing includes a vast array of strategies, consisting of mechanical testing, chemical evaluation, non-destructive screening, and thermal analysis. These examinations give important info about the toughness, firmness, versatility, and resistance of materials to aspects such as tension, heat, rust, and wear. By recognizing these properties, makers can make informed decisions about material option and style, bring about the production of secure and premium items.

Furthermore, products testing is crucial for quality assurance and item development. It assists recognize any type of imperfections or defects in materials, enabling manufacturers to correct them prior to the item reaches the market. This makes certain that items are safe for use and execute as intended, reducing the danger of crashes, failings, and costly recalls.

Assessing Performance of Products

How can materials be examined for efficiency? Assessing the performance of materials is essential in different markets, from building and construction to production. To ensure the reliability and suitability of products for their desired applications, numerous analysis approaches are utilized.

One typical method is mechanical testing, which involves subjecting materials to numerous stress and anxiety conditions to identify their elasticity, durability, and stamina. Tensile tests measure the optimum pressure a material can hold up against prior to breaking, while influence examinations evaluate exactly how well a material can soak up unexpected shocks. Additionally, hardness examinations establish a product's resistance to indentation or damaging.

Chemical analysis is another essential approach for examining material efficiency - materials test lab. By evaluating the structure of a material, such as its important material and chain reaction, its resistance to rust, degradation, or chemical responses can be examined. This information is crucial for materials utilized in environments where exposure to extreme chemicals is anticipated

Moreover, ecological testing can review the performance of materials under certain problems, such as severe temperatures, humidity, or UV exposure. These examinations simulate real-world conditions and assist identify any type of potential weaknesses or restrictions in a product's performance.

Ensuring Security in Product Use

By performing thorough examinations of products' efficiency, security in material usage can be ensured. Guaranteeing the security of materials is of utmost significance in different industries, consisting of building and construction, automotive, and aerospace.One trick facet of making certain safety navigate to this website in material usage is conducting rigorous screening and evaluation during the development and production phases. This includes evaluating the material's architectural honesty, stamina, toughness, and resistance to outside elements such as temperature level, stress, and chemicals. Rigorous testing assists identify any kind of prospective weak points or problems in the product, permitting necessary alterations or enhancements to be made.

Furthermore, official site it is important to consider the compatibility of products with their designated applications. Compatibility screening makes sure that the material will not respond negatively with various other compounds or parts in the system, which could cause security risks. This is especially vital in sectors where materials enter contact with different chemicals or are subjected to severe conditions.

In addition to screening, proper handling, storage, and upkeep of products are vital for guaranteeing security. Clear standards and protocols need to be established to lessen the risk of mishaps, such as leaks, spills, or fires. Routine examinations and upkeep should likewise be lugged out to identify any indications of deterioration or damages that can compromise the material's security.

State-of-the-Art Screening Methods

Cutting edge testing strategies play a crucial role in evaluating the efficiency and security of materials in numerous markets. These sophisticated techniques permit precise and dependable assessment of material properties, aiding to make sure that items fulfill quality criteria and abide with security policies.One such method is non-destructive testing (NDT), which makes it possible for the analysis of products without creating damages or altering their stability. NDT techniques include ultrasonic testing, radiography, and magnetic fragment screening, to name a few. These techniques are specifically useful in sectors such as aerospace, auto, and building and construction, where the integrity of materials is of utmost value.

In addition, progressed logical strategies such as scanning electron microscopy (SEM) and X-ray diffraction (XRD) provide comprehensive information concerning the microstructure and composition of materials. These strategies aid recognize any type of defects, pollutants, or adjustments in product buildings that may affect efficiency or security.

Advantages of Accurate Test Results

Precise examination outcomes provide beneficial understandings into the efficiency and More about the author security of products, permitting sectors to make educated choices pertaining to item high quality and compliance with laws. These exact examination results offer a number of advantages that are essential for the success of companies in various industries.First of all, precise examination results aid in identifying the top quality of products. By reviewing the performance features of materials, industries can make certain that their products fulfill the needed specs and requirements. This is particularly crucial in markets such as aerospace, auto, and building, where the use of low-grade materials can result in potential dangers and tragic failings to human lives.

Secondly, precise examination results help in identifying potential weaknesses or problems in products. By carrying out detailed screening, sectors can identify any useful or structural issues that may compromise the safety and reliability of their products. This allows them to make required enhancements and modifications to improve the performance and sturdiness of materials, leading to much safer and much more trustworthy final result.

Final Thought

To conclude, materials testing plays a vital role in examining the efficiency and ensuring the safety of different products. By making use of state-of-the-art testing methods, exact examination results can be obtained, which supply useful understandings right into the quality and reliability of materials. These test results have many advantages, such as helping with informed decision-making, improving product advancement, and making sure governing conformity. Investing in a materials screening lab is crucial for companies and sectors looking for to optimize performance and security in their material use.The relevance of materials screening in making certain performance and safety can not be overemphasized. Tensile tests measure the optimum force a material can hold up against before breaking, while impact tests evaluate how well a product can absorb abrupt shocks.By carrying out detailed analyses of materials' efficiency, security in product usage can be ensured.In verdict, products testing plays a crucial function in evaluating the efficiency and guaranteeing the safety of various products. Spending in a materials screening lab is necessary for industries and companies looking for to maximize performance and safety and security in their material use.

Report this wiki page